The global race for the next generation of energy storage is centered on Solid-State Batteries (SSBs). While the potential for higher energy density and enhanced safety is clear, the transition from lab-scale prototypes to mass production remains a challenge. One of the most critical hurdles is ensuring perfect interface contact between solid electrolytes and electrodes.

To bridge this gap, we are proud to introduce our high-performance Warm Isostatic Press (WISP), a machine specifically engineered for SSB pilot research and large-scale manufacturing.

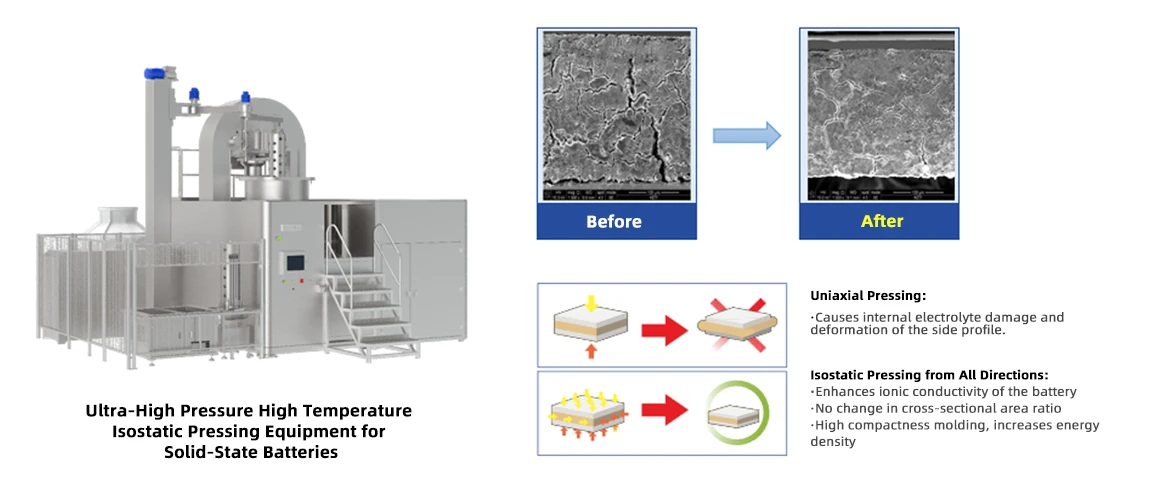

Why Isostatic Pressing is Critical for Solid-State Batteries

Unlike traditional liquid lithium-ion batteries, solid-state batteries rely on the seamless contact of solid materials. Any microscopic voids or "air gaps" at the interface increase internal resistance, leading to poor cycle life and reduced power output.

Warm Isostatic Pressing (WIP) applies uniform pressure from all directions using a liquid medium at elevated temperatures. This process:

● Eliminates Voids: Ensures 100% densification of the solid electrolyte layer.

● Enhances Interface Contact: Minimizes interfacial impedance between the cathode, electrolyte, and anode.

● Improves Structural Integrity: Prevents delamination during high-rate charging and discharging.

Engineering Excellence: 600MPa at 150°C

Our latest WISP system is designed to meet the most rigorous industrial requirements. With asteady-state working pressure of 600MPa, it provides the extreme force necessary to densify even the toughest ceramic electrolytes, such as sulfides and oxides.

Coupled with a maximum working temperature of 150°C, the equipment allows for the "softening" of certain battery components during pressing, ensuring a more homogeneous and robust cell structure without damaging sensitive chemical compositions.

Large-Format Capability for Industrial Scaling

One of the standout features of this system is its capacity. It is designed to handle large-cell formats with dimensions up toL: 950mm * W: 270mm * H: 30mm. This makes it one of the few machines on the market capable of supporting the production of large-format automotive-grade solid-state battery cells.

Technical Superiority and Precision Control

Efficiency and precision are the backbones of our design. The system utilizes a dual-media approach:hydraulic oilfor the power system andthermal oilas the working medium. This ensures both safety and high-performance thermal conductivity.

● Rapid Pressurization:Reaching 600MPa in under 5 minutes, significantly reducing cycle times and increasing throughput.

● Thermal Stability:With a temperature deviation of only ±3°C, your battery materials undergo uniform heat treatment, ensuring batch-to-batch consistency.

● Pressure Precision:Maintaining stability within ±2% during the hold time is vital for delicate electrolyte layers that are prone to cracking under fluctuating loads.

Technical Specifications at a Glance

|

Item |

Parameters |

Remarks |

|

Chamber Diameter |

Φ300mm |

|

|

Effective Depth |

1000mm |

|

|

Max Design Pressure |

660MPa |

|

|

Max Working Pressure |

600MPa |

|

|

Max Working Temperature |

150°C |

|

|

Max Temp. Deviation |

±3°C |

Measured in medium under steady state |

|

Hydraulic Power Medium |

Hydraulic Oil |

|

|

Pressure Flow Rate |

≥3L/min |

|

|

Pressure Stability |

Within ±2% |

During steady state |

|

Pressurization Time |

≤5min |

0 to 600MPa |

|

Working Medium |

Thermal Oil |

Ready for the Future of Battery Manufacturing

Whether you are in the R&D phase optimizing electrolyte formulations or moving into mass production for the electric vehicle market, our Warm Isostatic Press is the "missing link" in your production line.

By combining extreme pressure, precise temperature control, and a large processing volume, this equipment is the essential tool for any organization serious about leading the solid-state battery revolution.

Contact Our Experts

Ready to elevate your solid-state battery production? Our engineering team is available to discuss how our 600MPa WISP can integrate into your existing workflow.