A voltagem de uma bateria de lítio está intimamente relacionada aos potenciais dos eletrodos dos materiais do cátodo e do ânodo. As variações de voltagem entre baterias de lítio que utilizam diferentes materiais decorrem principalmente dos seguintes fatores:

Impacto das propriedades químicas dos materiais dos eletrodos

Baterias de lítio operam através do movimento de íons de lítio entre o cátodo e o ânodo durante a carga e a descarga. As propriedades químicas dos materiais do eletrodo desempenham um papel crítico, determinando diretamente a voltagem da bateria. Por exemplo, o óxido de lítio-cobalto (LiCoO₂), um material de cátodo comum, aproveita o alto potencial redox do cobalto. Durante a operação, o LiCoO₂ libera íons de lítio e elétrons prontamente. Quando pareado com um ânodo de grafite, a voltagem resultante da bateria atinge aproximadamente 3,7 V. Em contraste, o fosfato de ferro-lítio (LiFePO₄), devido ao menor potencial redox do ferro em comparação ao cobalto, fornece uma voltagem estável de cerca de 3,2 V quando combinado com um ânodo de grafite. Essas diferenças surgem de variações na distribuição da nuvem de elétrons e nas estruturas químicas entre os elementos, que influenciam sua capacidade de ganhar/perder elétrons e liberar íons de lítio, levando, em última análise, a voltagens divergentes da bateria.

Variações de tensão causadas por diferenças na estrutura cristalina

A estrutura cristalina dos materiais também impacta significativamente a voltagem da bateria de lítio. Materiais ternários (Li(NiCoMn)O₂) servem como um excelente exemplo, onde os efeitos sinérgicos do níquel, cobalto e manganês otimizam a estrutura cristalina. Essa otimização facilita vias de difusão de íons de lítio mais suaves e intercalação/desintercalação mais fáceis. Quando combinados com um ânodo adequado, esses materiais exibem um platô de voltagem mais alto, tipicamente entre 3,6–3,7 V. Por outro lado, o óxido de lítio-manganês (LiMn₂O₄), com sua estrutura espinélio, enfrenta desafios como a dissolução de íons de manganês durante o ciclo. Isso dificulta a difusão de íons de lítio, resultando em uma voltagem relativamente menor de aproximadamente 3,0 V. Assim, diferenças na estrutura cristalina afetam diretamente a eficiência do transporte de íons de lítio e a voltagem final da bateria.

Relação entre densidade de energia e voltagem

Existe uma forte correlação entre a densidade energética dos materiais dos eletrodos e a voltagem da bateria. Materiais com alta densidade energética armazenam mais energia por unidade de massa ou volume, o que frequentemente corresponde a voltagens mais altas. Por exemplo, materiais ternários com alto teor de níquel alcançam maior densidade energética e voltagens mais elevadas à medida que o teor de níquel aumenta. Isso melhora o desempenho geral da bateria e atende às demandas por aplicações de alta energia. Em contraste, os materiais de baterias de lítio de primeira geração, com suas densidades energéticas mais baixas, têm dificuldade em armazenar energia suficiente por unidade, resultando em voltagens mais baixas que não atendem aos requisitos modernos de alta energia e voltagem.

Em resumo, as diferenças de voltagem entre baterias de lítio que utilizam materiais distintos decorrem dos efeitos combinados das propriedades químicas, estruturas cristalinas e densidades de energia dos materiais dos eletrodos. A compreensão desses fatores fornece insights cruciais sobre o funcionamento das baterias de lítio e apoia o desenvolvimento de baterias de lítio mais eficientes e de alto desempenho.

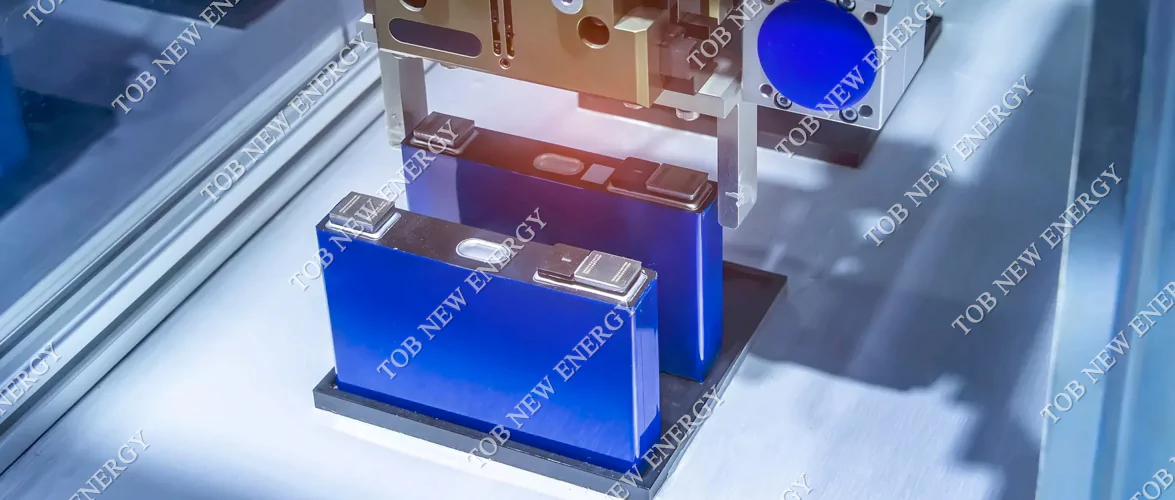

NoTOB NOVA ENERGIA, estamos comprometidos em ser seu parceiro estratégico no avanço das tecnologias de armazenamento de energia. De alto desempenho cátodomateriais/ materiais de ânodoe especializadoligantespara engenharia de precisãoseparadorese sob medidaeletrólitosOferecemos um conjunto completo de componentes de bateria projetados para elevar a confiabilidade e a eficiência do seu produto. Nossa oferta abrange tecnologias de pontaequipamento de fabricação de bateriasetestador de bateria, garantindo integração perfeita em todas as etapas da produção da bateria.

Com foco em qualidade, sustentabilidade e inovação colaborativa, oferecemos soluções que se adaptam às crescentes demandas do setor. Seja otimizando projetos existentes ou desenvolvendo baterias de última geração, nossa equipe está à disposição para apoiar seus objetivos com expertise técnica e atendimento ágil.

Vamos construir juntos o futuro do armazenamento de energia. Entre em contato conosco hoje mesmo para descobrir como nossas soluções integradas podem acelerar seu sucesso.